1280 mm

Options

- Special chutes

- ABS anti-lock system on the screw (See the ABS system)

- Grills: 4, 5 and 8 mm with conical or inclined holes

- Large capacity hopper: For greater autonomy, with raised grinder feet

- Level sensors in the hopper

- SMC metal detection system in the screw trough (screws, nuts, etc.). The grinder and screw motors are stopped automatically when a conductive material is detected.

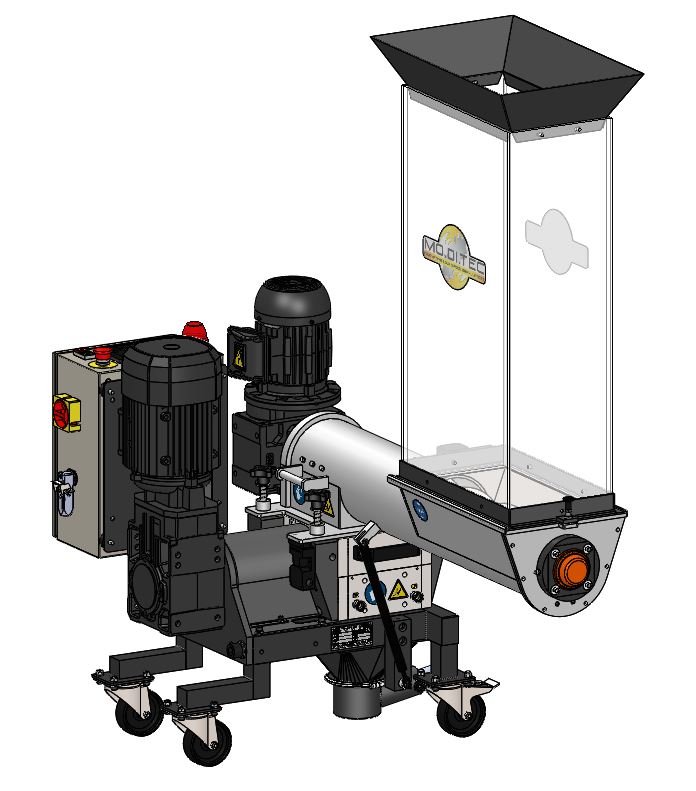

BM 170 Screw

Visual shows screw and 4 Kw horizontal drive

BM 170 screw and BM 340 screw grinders collect large injection sprues directly beneath the machine’s mould thanks to their endless screw. To reduce the footprint, screw models are also available in a compact version. All screw versions can be equipped with a chute (optional) enabling large sprues to be collected at the base of the machine beneath the manipulator, for example.

- Transmission by elastic coupling

- Slide system (see options catalogue page 9)

- Cutting chamber: 236 x 176 mm

- 170 mm diameter rotor: 1

- Movable blades: 3 in special wear resistant steel, progressive cutting

- Adjustable fixed blades: 2 in special wear resistant steel

- Rotation speed: 260 rpm

- Noise level: < 75 dBa depending on the material

- Cooling circuit in the cutting chamber block

- Hopper (3 L) with adjustable suction vessel and 38 mm diameter suction tube

- Mechanically welded frame with 4 castors, including 2 with brakes

- Electrical box with PLC and LCD screen for managing settings

- Safety switches for chute opening and hopper removal

- RAL 7021 (black grey)-9006 (white aluminium)

- Dimensions with soundproof chute: L: 714 mm – W: 623 mm – H: 1282 mm

Bespoke